In the thesis one engine block is used to verify the effectiveness of the optimization method. DESIGN OF DOWN-RUNNER OR SPRUE 21 Calculate the weight of liquid metal to be poured includes the casting the feeder and all elements of gating system 22 Choose location and design of gating system.

Pdf Gating System Design For Casting Thin Aluminium Alloy Al Si Plates Semantic Scholar

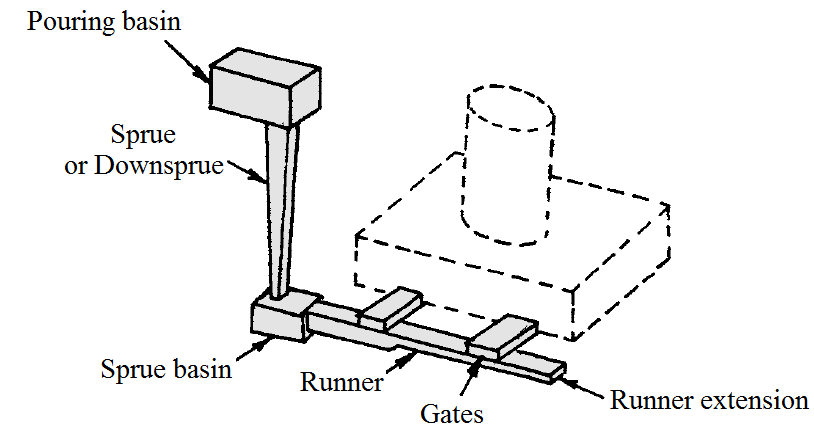

The gating system in sand casting includes.

. Causing shrinkage of objects in the mold. 280 Bronze Tin 190 Brass 180 gating Bottom 130 gating Top by given constant a is K s W K t time Pouring 2 3 2 6 Intricately shaped thin walled castings with Grey CI mass casting with gates and risers kg K 3 a constant as given below 7 For casting above 450 kg and upto 1000 kg where K 4 a constant as given below s W K t time. Defects may arise in the casting that are direct results of poor gating practices implemented by blindly following gating guidelines.

Because of poor design of gating system. Casting is a suitable economical manufacturing process for various components. Gatingriser system design is optimized to improve casting quality.

Mainly depend on gating system. Make metal penetrate the mold wall. If the gating system is designed incorrectly the following errors can occur.

Schematic of a traditional gating system layout. There are several objectives to efficient gating design. Risers and Riser Design Riser must be separated from the casting upon completion so the connection area must be as small as possible Figure 11-13 Schematic of a sand casting mold showing a an open-type top riser and b a blind-type side riser.

Economic and maximizing casting yield. Due to the existing Flat gate system in the existing model the following defects occur in the casting leading to rejection and loss in quality. See Appendix 1 and Appendix 2.

Availability of modern software tool give designer an insight into the detail of fluid flow heat transfer. It may experience different defects such as cracks hotspot mis-run etc. Poorly designed gating system results in casting defects.

Compared with the initial design it is found that the optimized casting design can decrease porosity around. This article discusses various desirable design considerations for the gating system. Hence to design a good gating system one must know the behavior of fluid flow during mould filling process.

A gating system refers to all passageways through which the molten metal passes to enter the mold cavity. 21 Casting Defects in. Chapter 5 Gating System Design for a Multi-Cavity Die-Casting Die The gating system is a channel or a passage in the die through which the molten metal reaches the cavities.

Proper design of an optimized gating system will be made easier by the application of several. Pouring bushbasin for larger casting 2. Gatingriser system design is critical to improving casting quality.

Another major element is filter or slag trap which usually placed in runner or between runner and ingate to filter slag and other inclusions. Download full-text PDF Read full. He has a diverse industrial background and has held management positions in the metal casting and related industries for over 30 years.

That at the same time facilitates the editing of die casting design during or after the course of the design process. Short-length connections are most desirable. The gating system design refers to the design of its various elements such as gate runner overflow and biscuit which are described later in Section 51.

The basic components of a simple gating system are pouring basin sprue runner gates. The side riser is a live riser receiving the last hot metal to enter the mold. Jerry Thiel Jerry Thiel is the Director of the Metal Casting Center at the University of Northern Iowa.

Casting Design Guide f Edited by Dr. Pouring basin or. The riser and gating system in casting process is shown in Figure 8.

By gaining a better understanding of these methods and practices improvements in casting yields and integrity should be realized. Mould filling is a. Hence a new optimized gate design is necessary in order to remove defects from the casting.

A gating system is the conduit network through which liquid metal enters a mold and flows to fill the mold cavity where the metal can then solidify to form the desired casting shape. Most engineering problems casting designs done trial and error basis. The main function of gating system is to lead clean molten metal from ladle to the casting cavity ensuring smooth uniform and complete filling.

Riser for sand casting process 361 Design Requirements of Risers 1. A key element in producing quality castings is the proper design and sizing of the gating and riser systems. Gating and riser system are designed with the help of mathematical formulae.

A gating system controls mould filling process. The objective of project is to design and simulate gating and risering system components by using simulation technology to get defect free casting. Gating system design is crucial in controlling the rate and turbulence in the molten metal being poured the flow of liquid metal through the castings system and the temperature gradient within the metalcasting.

23 Determinedecide on total filling time of casting. In Casting design the gating riser system design has a direct influence on quality of cast component. Hence a good gating system will create directional solidification throughout the casting since the flow of.

Pdf Design Of Gating And Riser System For Grate Bar Casting

Pdf Optimized Design Of Gating Riser System In Casting Based On Cad And Simulation Technology Semantic Scholar

Pdf Automation Of Gating System Parameters For Green Sand Iron Castings

Pdf Gating Design Criteria For Sound Casting Semantic Scholar

Types Of Gating System In Casting Process Bajrang Engineering

0 comments

Post a Comment